RMPL represents Quick Connectors Inc. in India and has facilitated the sales and service of the QCI range of products with leading private and government oil companies. QCI is a manufacturer of well head and packer penetrators for use with Electric Submersible Pumps. The company has over 2 decades of experience internationally in the oil Industry and is headquartered at Houston, USA, with a branch sales office in Dubai which is focused on supporting the Indian market.

QCI systems are backed by high quality designs, adaptable or can be retrofitted to existing systems and meet the highest safety standards. RMPL personnel have been trained to provide agreed service for the products during and after installation.

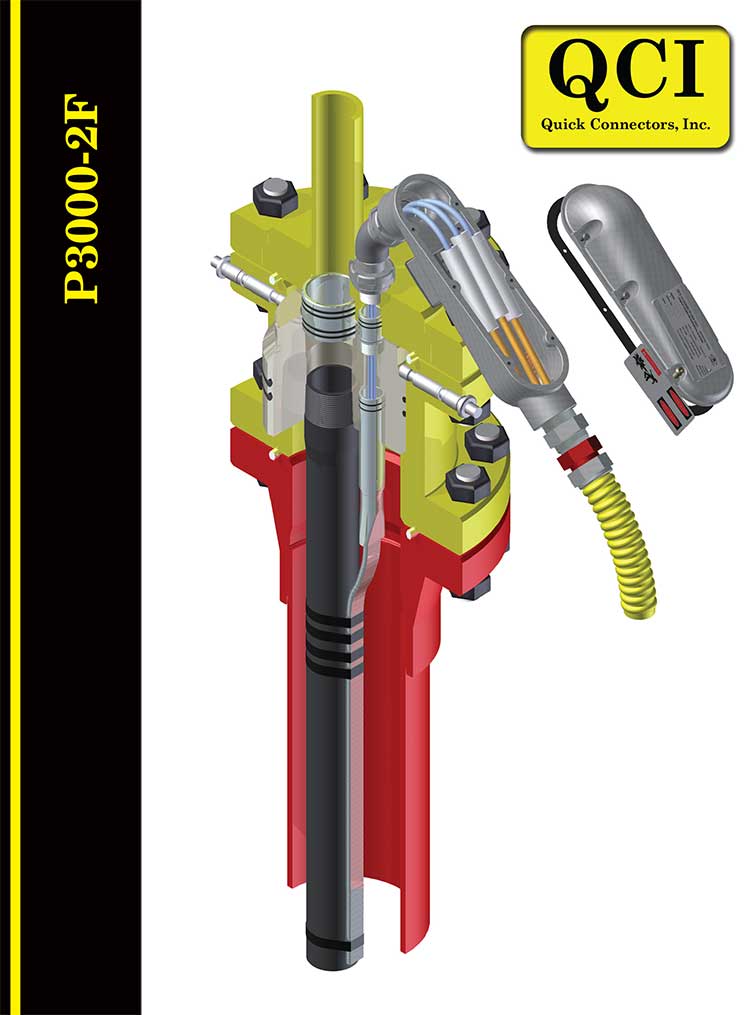

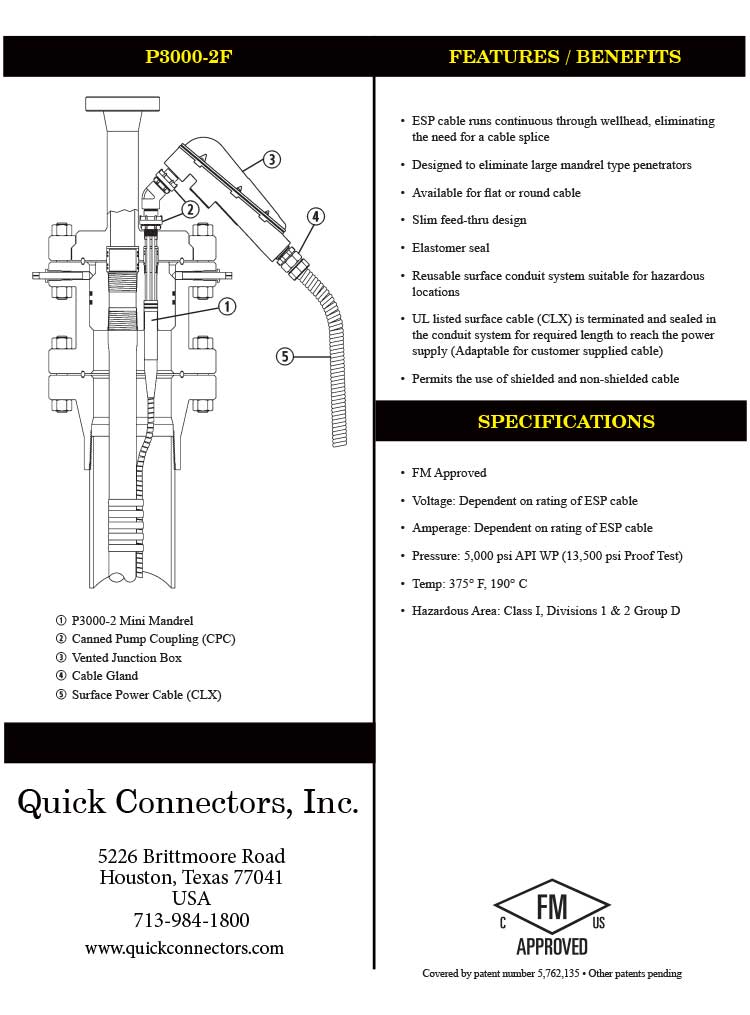

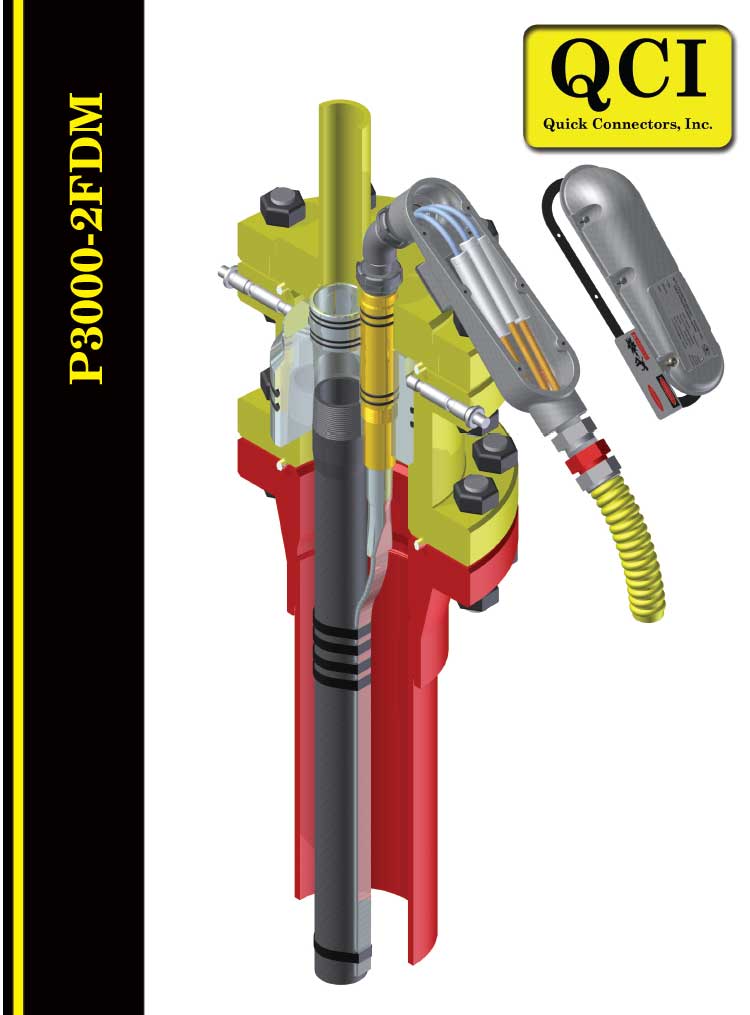

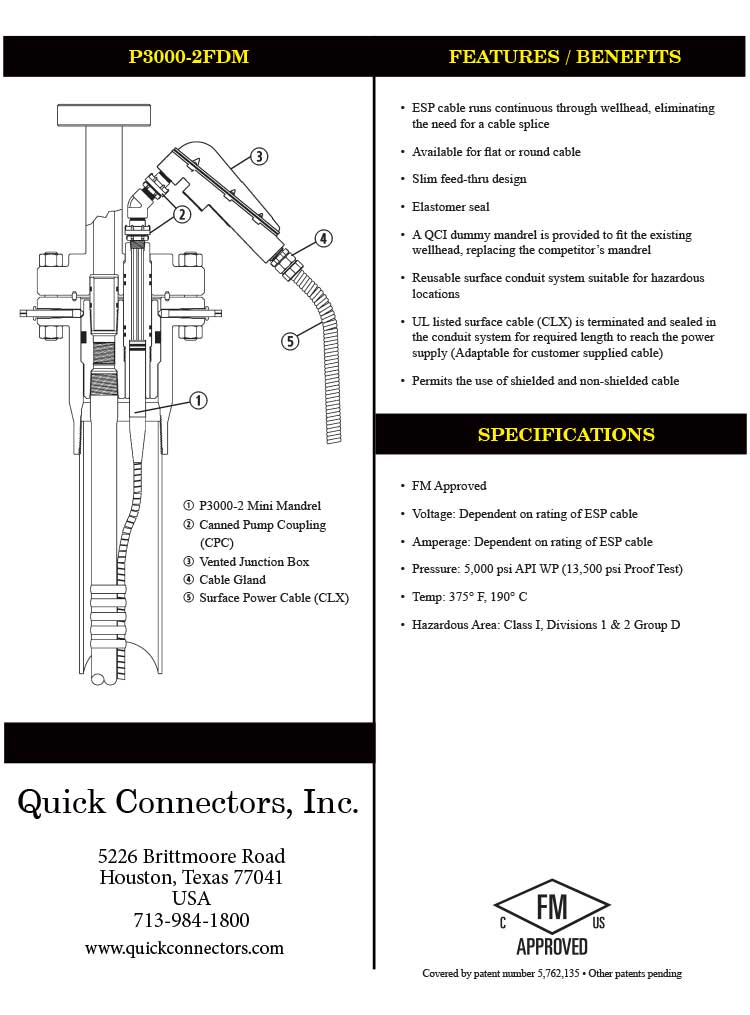

P3000-2 – Wellhead Penetrator

The P3000-2 is a single-mandrel, field-installed, 1-3/4” diameter penetrator system that can be installed on either flat or round cable and has the added benefit of being able to be retrofitted into existing wellheads using a hollow Dummy Mandrel profile of a competitive penetrator system. The P3000-2 penetrator system is unique in that it offers a direct feed-through of the pump cable to the surface without requiring a splice or downhole connection of any kind. Once on the surface, the downhole pump cable is connected to the surface cable within the QCI Conduit Box, available in both Class 1 Division 1 and Class 1 Division 2 configurations. The P3000-2 system is rated for up to 5,000 psi API WP (13,500 psi Proof Test) and – since the P3000-2 system is a direct feed-through – the maximum rating for voltage and amperage is dependent on the pump cable. Please note that QCI’s P3000-2 system carries ATEX and CSA certifications from FM Approvals and we are currently pursuing IECEx certification for compliance in additional international markets.

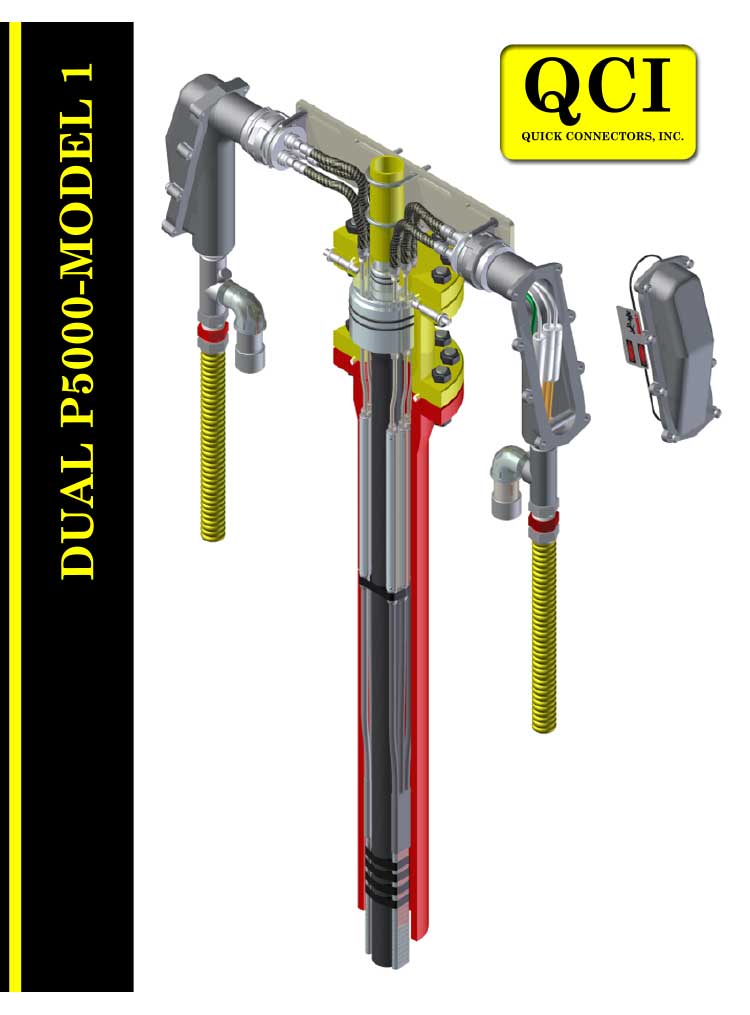

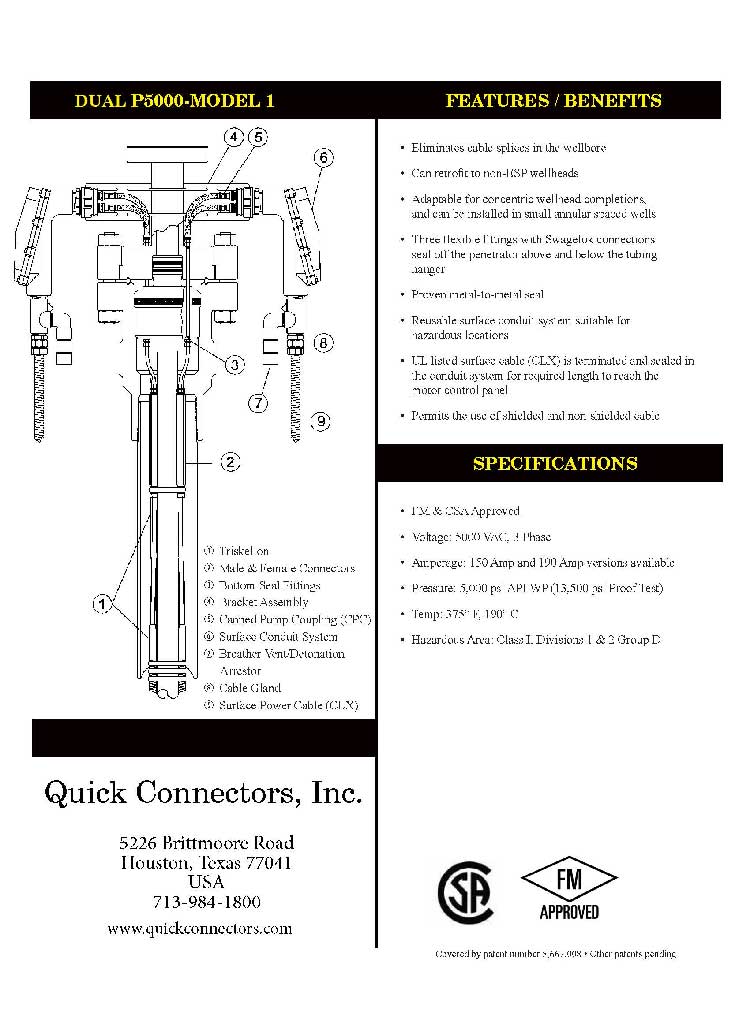

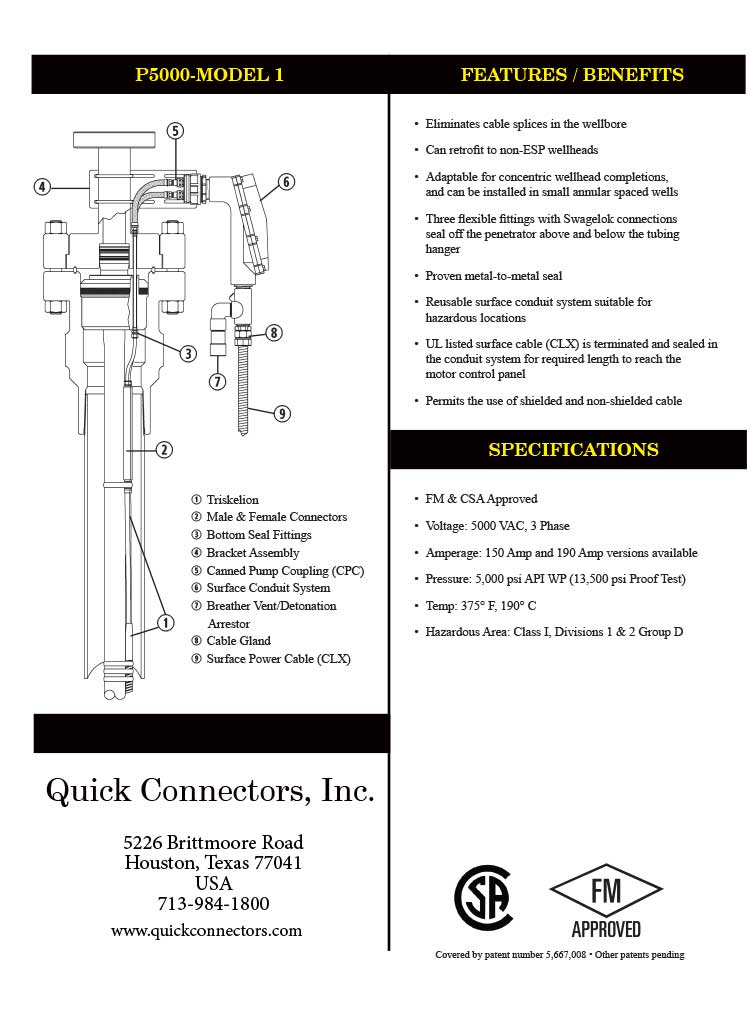

P5000 (Model 1) – Wellhead Penetrator

The P5000-Model 1 is a three-legged, field-installed, penetrator system. The P5000 requires three, 3/8” NPT ports for installation in the wellhead which allows for a system that is perfect for new applications or which can be easily adapted to fit existing applications where the wellhead is able to be modified. The P5000 system is designed for installations in wells where there is minimal annular space allowed between the casing and the production tubing or in situations where the operator wishes to keep the well concentric. Like the P3000-2 system, the P5000-Model 1 system is designed to eliminate splices to the pump cable and instead uses a crimped-on socket and pin connection contained within an EPDM rubber boot and outer sleeve. Once on the surface, the QCI penetrators are connected to the surface cable within the QCI Conduit Box, available in Class 1 Division 1 and Class 1 Division 2 configurations. The P5000-Model 1 system is rated for up to 5,000 psi API WP (13,500 psi Proof Test) with a maximum voltage of 5000 VAC and both 150 and 190 Amp systems available. Please note that QCI’s P5000-Model 1 system carries ATEX and CSA certifications from FM Approvals and we are currently pursuing IECEx certification for compliance in additional international markets.

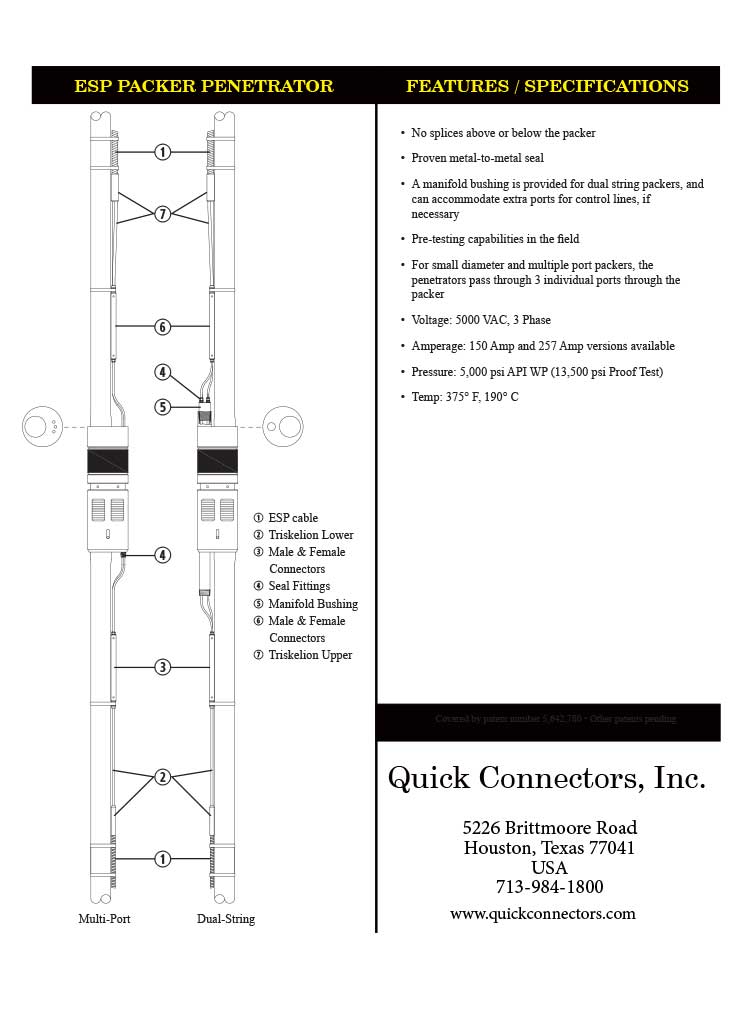

Packer Penetrator

The QCI Packer Penetrator system is a variant of the P5000 three-legged penetrator system that can be used in most dual-string packers (through the use of a manifold bushing) or multi-port packers requiring a tighter fit (by using three, 3/8” NPT ports). The QCI packer penetrator is rated for up 5,000 psi API WP (13,500 psi Proof Test) with a maximum voltage of 5,000 VAC and 257 Amps.